Induction heater: how does induction heating work exactly?

| 10 September, 2019

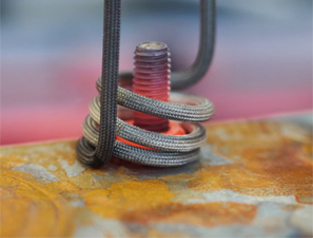

By means of an induction heater you can heat iron-containing materials safely and quickly. This causes the materials to expand and allows you to easily disassemble rusted, glued or clamped iron-containing parts. It is a technique that is used in many different sectors. Think for example of the automotive, nautical, petrochemical industry, infrastructure, industry and aerospace.

How does it work exactly?

Induction heaters operate by means of electronic induction heating. This enables you to easily and quickly disconnect ferrous materials, without having to use a gas burner. Typical for induction heating is that mainly the outer structural parts are heated. This is in contrast to a gas burner where everything is heated. Moreover, induction heating is known for its efficiency. Within tens of seconds you can heat the material up to 600 degrees.

Alternative methods

There are still companies that use gas burners to heat materials. However, there are several drawbacks to this. For example, the use of open flames in the workplace is dangerous. In addition, it is not possible to use a gas burner for targeted heating. The parts that you don’t want to be heated are also heated. This also means there is a risk of collateral damage. Things such as plastic brakes, fuel lines, and expensive wiring.-

What are the advantages?

1. Always the right coupling

The iDuctor comes with a set of eight spirals in different metric sizes. This way you can always make the right connection between the iDuctor and the object to be heated. Furthermore, the coils are easy to change manually thanks to the unique, patented clamping mechanism.

2. Simple working

The iDuctor can also be used in hard-to-reach places. Moreover, the iDuctor is easy to operate with one hand. In addition, the spirals can easily be changed without tools.

3. Efficiency

Induction is an efficient and safe way of heating. In addition, it is possible to set the power and switch-off time of the iDuctor. This ensures that consistent results are achieved.

4. High productivity

With the iDuctor it is possible to heat objects within tens of seconds. This will save a great deal of time and thus increase productivity.

5. Energy saving

Heating by means of induction heating is extremely efficient. With an efficiency of almost 90%, induction heating is one of the most efficient ways to convert energy into heat. It is not difficult to imagine that this will result in enormous savings on your energy bill on an annual basis.

6. Safe working environment

Induction heaters are safe to use. Unlike gas burners there are no open flames. This also means that there are no problems with highly flammable substances. Therefore, it contributes to a better and safer working environment. In addition, you can also save on your insurance costs. In some countries, you can get up to 35% discount on your insurance premiums if you work without open flames in your workshop.

7. High quality

The iDuctor is produced in the Netherlands and is of the highest quality. It has an ergonomic design and is made of high quality materials. In addition, it is equipped with a unique patented clamping system. This makes it easy to change the spirals manually.

Tips for purchasing

- Always use the right spirals.

- Do not make the object red-hot.

- Do not overheat the iPad.

More information about induction tools?

Did you get interested in the iDuctor? Check out the different kits here or contact us for personal advice. If your specific application is not listed, custom solutions are also possible.

+31 (0) 88 060 65 00

+31 (0) 88 060 65 00  info@idtools.eu

info@idtools.eu